Project Portfolio

Cool roofs, also called reflective or high albedo roofs are typically light in colour and absorb less sunlight than a conventional dark-coloured roof. The net result is that a lower fraction of the incident solar energy (only about 17% or less) is absorbed by the structure. This increases occupant comfort, reduces the cooling load on the air conditioning systems as well as significantly increases the expected life of the building's roof. The magnitude of energy savings depends upon building type, level of roof insulation, ventilation rate between roof and ceiling, a/c size and efficiency, and of course, roof solar reflectance.

The environmental benefits of cool roofs are that they can decrease the urban heat island effect by reflecting most of the incident solar energy back into the sky as opposed to absorbing the heat and releasing it to the surroundings.

How we work

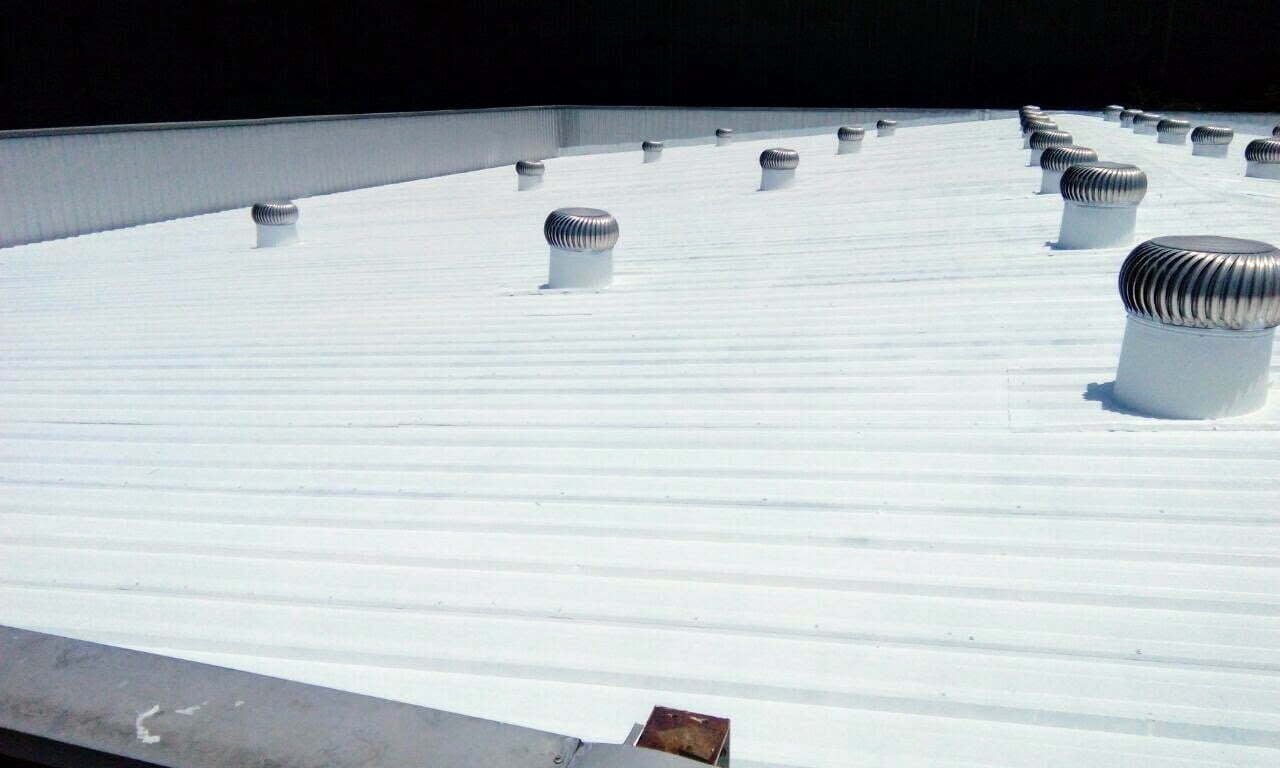

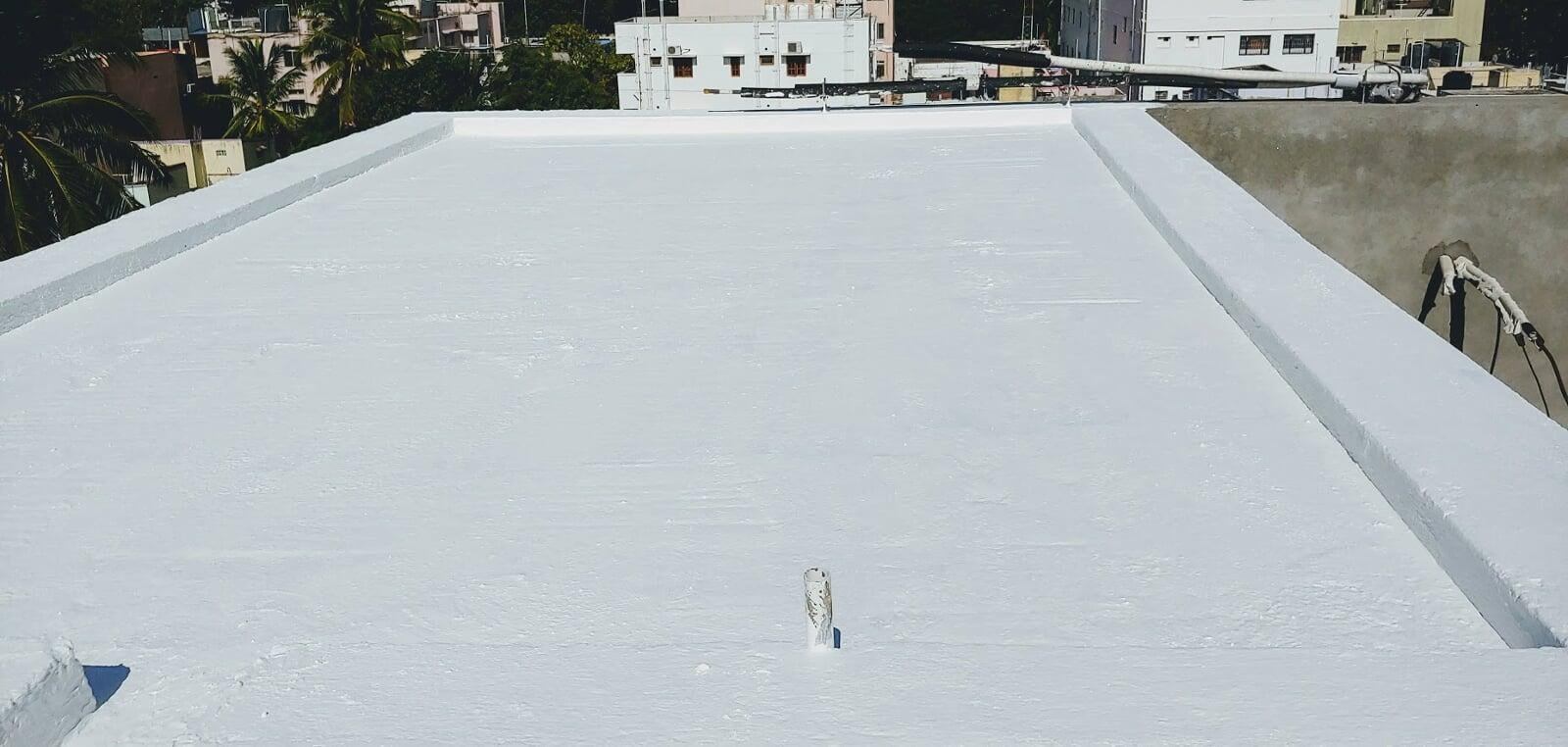

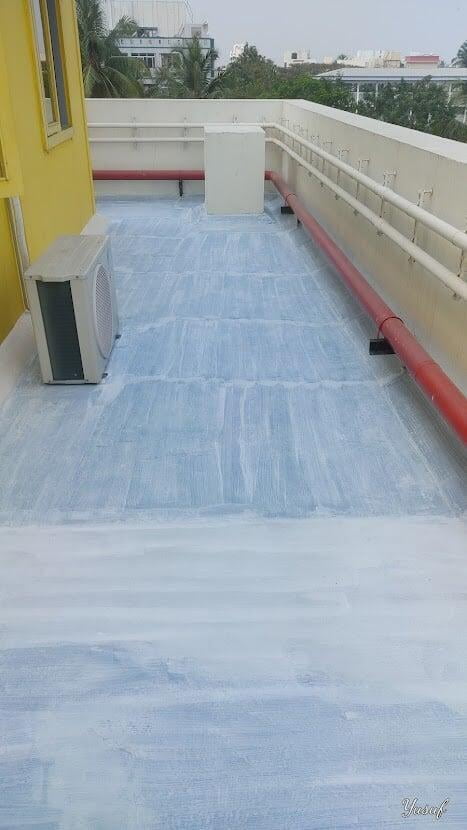

A cool roof is usually recommended for roof tops that are unlikely to be frequently visited during peak sunshine. The reflective nature of the coating gives a snow like effect causing the roof to look extremely bright. The BuildScape - Cool Roof solution provides the dual benefit of heavyduty waterproofing and high levels of heat reduction. We use products from Dr. Fixit - Exterior Coatings which are proven to be the highest performing and most durable cool roof products in the market. Our applicators are highly experienced and professionally trained waterproofing and cool roof specialists.

The scope of work involved applying the BuildScape - Cool Roof solution are:

- Understanding the client requirements and checking the project site for drainage and surface damage.

- A site clean up will be performed to clean the entire surface of dust, dried fungus, oil & grease and loose materials using wire brush technique.

- A systematic roof repair is carried out where the cracks and other damages are repaired using Dr.Fixit prescribed methods

- One layer of efflorescence resistant primer will be applied to provide adhesion, binding and fill small cracks.

- Two or Three coats of heat reducing & ‘Energy Saving’ elastomeric coating to achieve a minimum thickness of 120 microns.