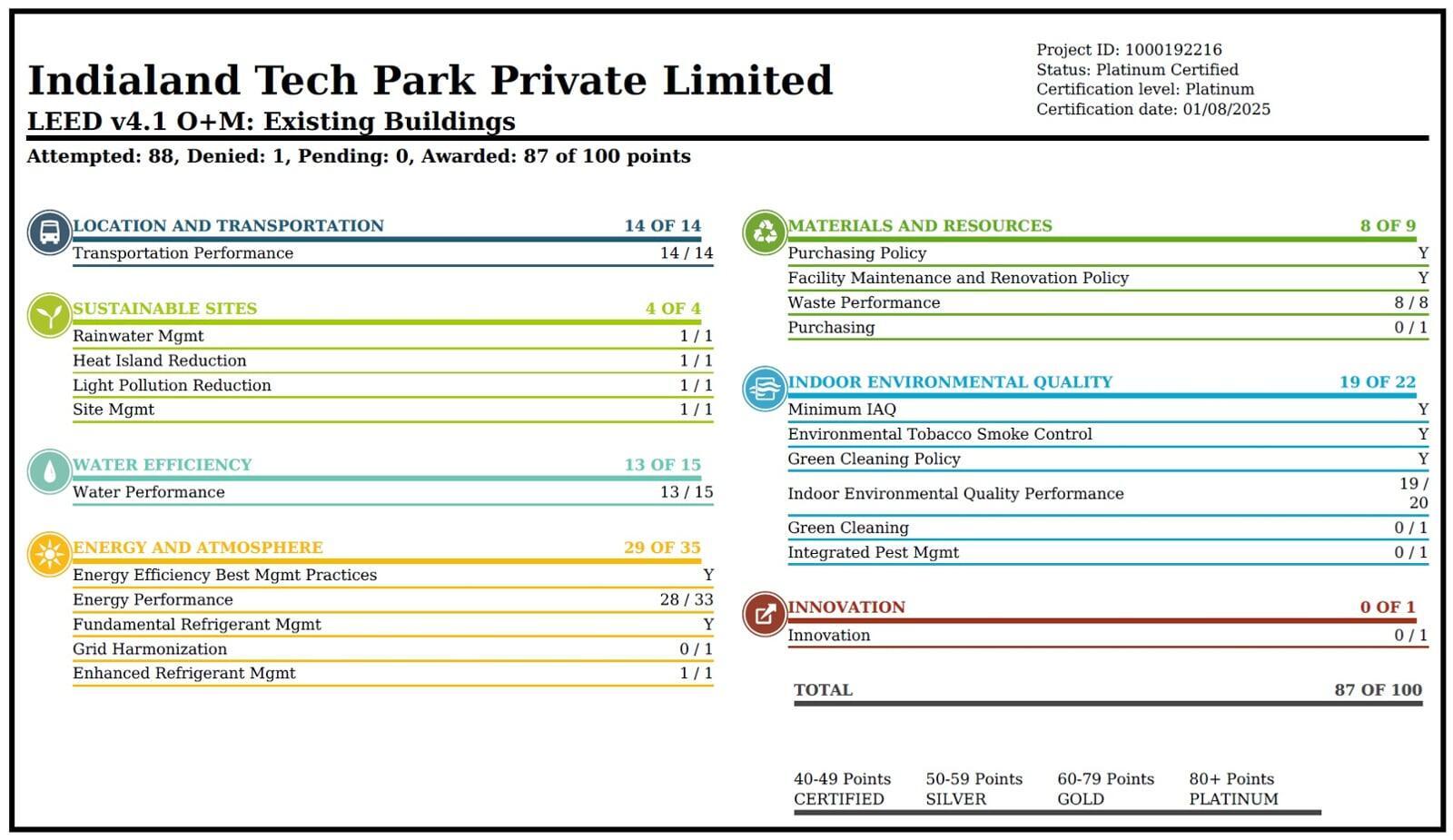

InHabit is proud to announce that India Land Tech Park, Coimbatore has been awarded the prestigious Platinum Rating in the LEED V4.1 Existing Buildings Operations and Maintenance Rating system.

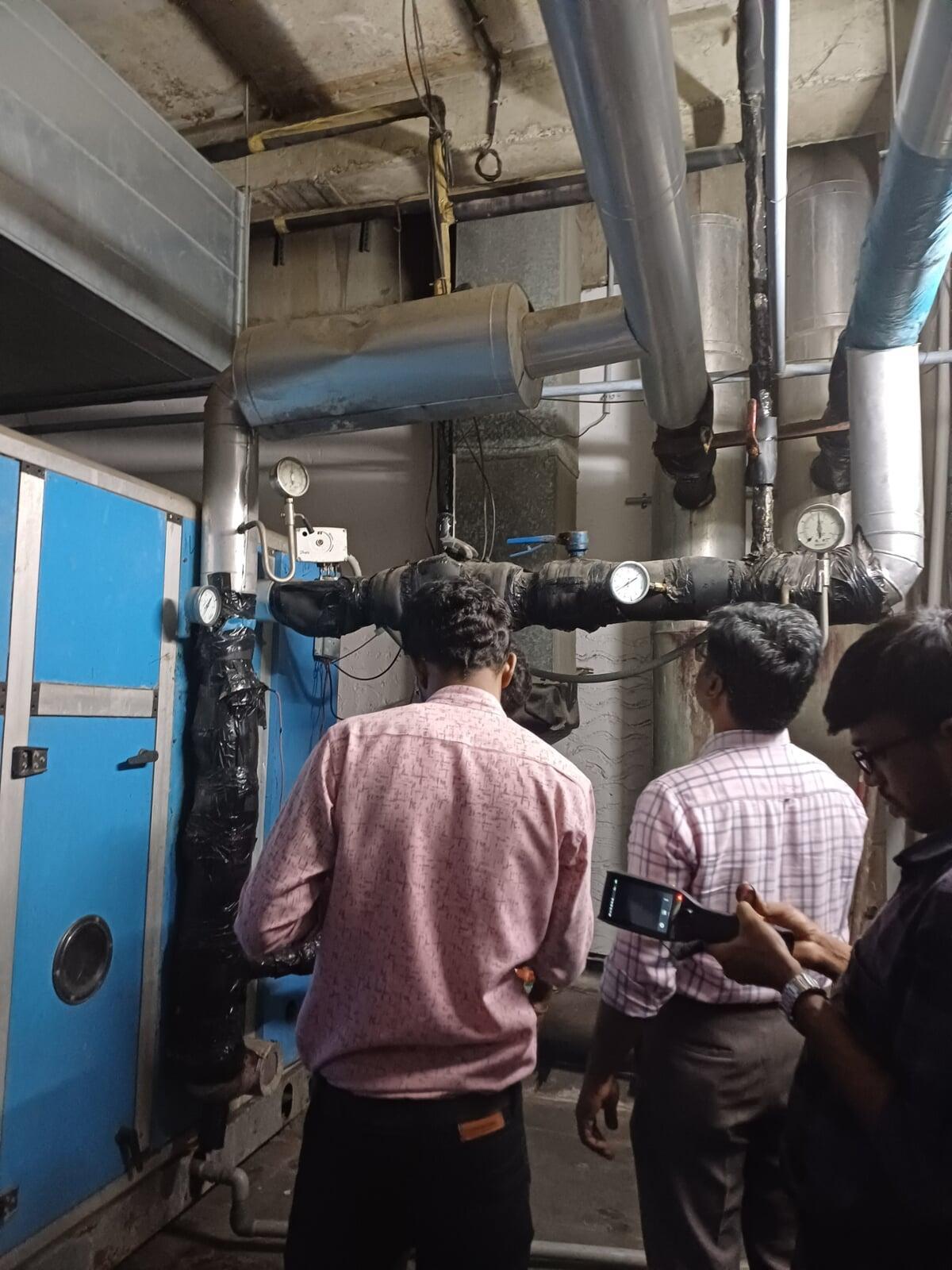

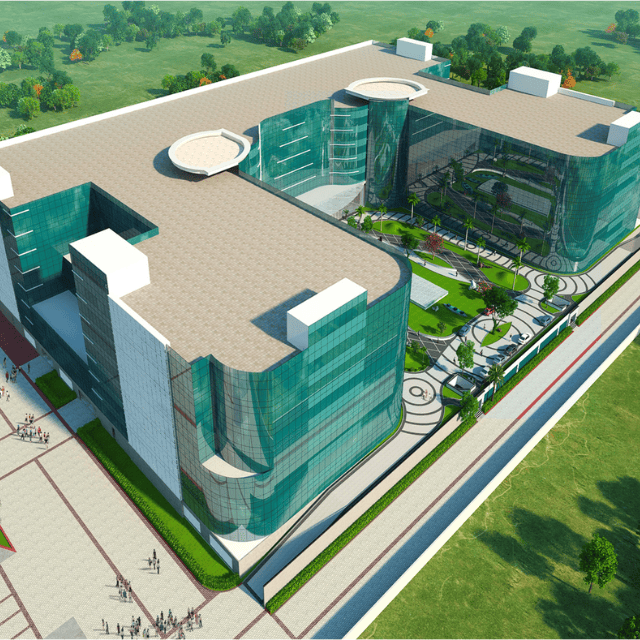

InHabit has provided green building consultation and ratings facilitation services to India Land Tech Park Private Limited for the largest IT technology park in their portfolio at Keernatham, Coimbatore, Tamil Nadu.

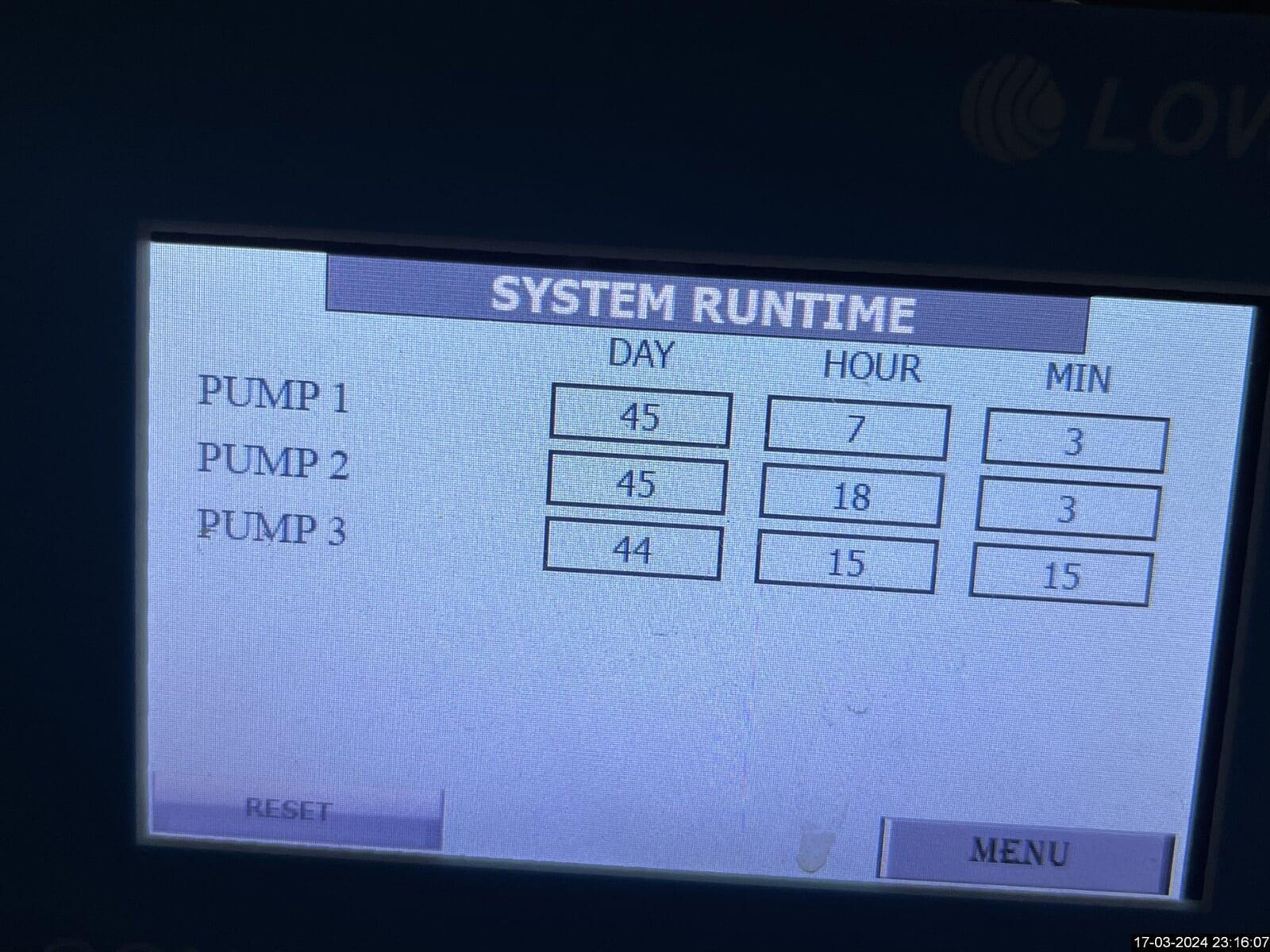

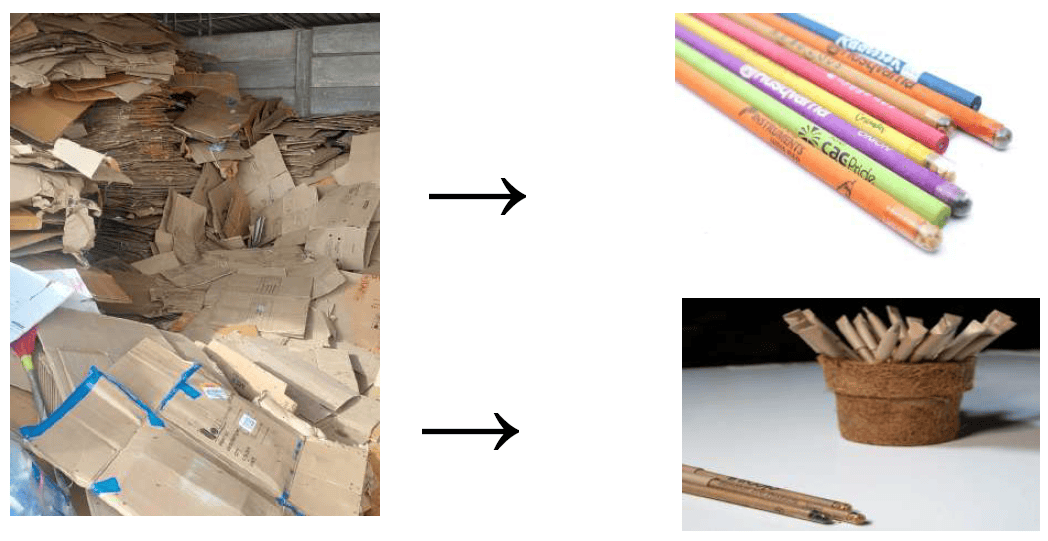

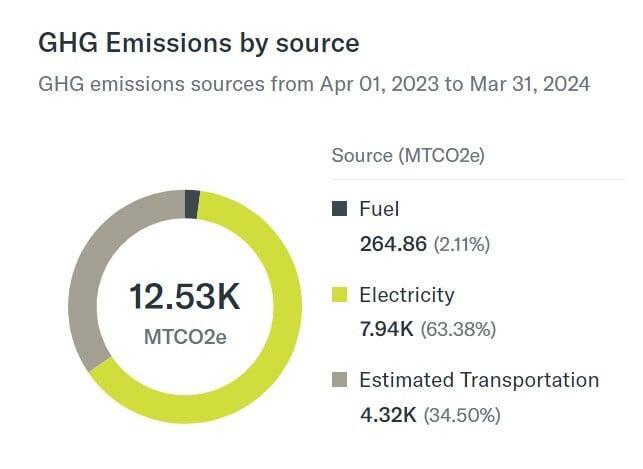

The technology park with a built-up area of over 1.5 million Square Feet is one of the largest commercial buildings in Coimbatore. The building with a phenomenal score of 87 out of the available 100 has exceeded Global and local averages in energy, water, waste, transportation and human experience criteria.